Provide you with the latest enterprise and industry news.

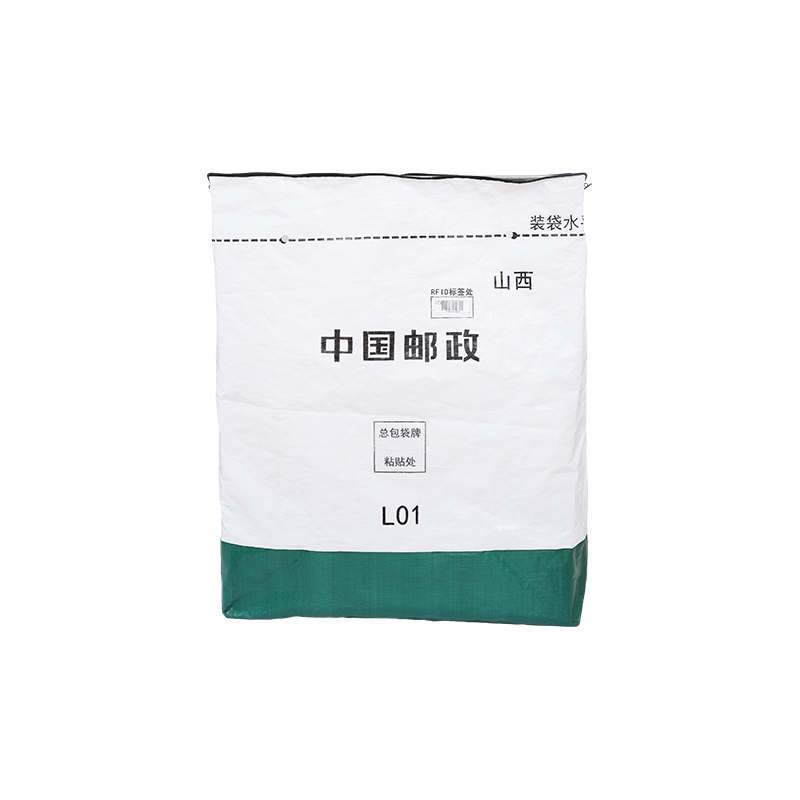

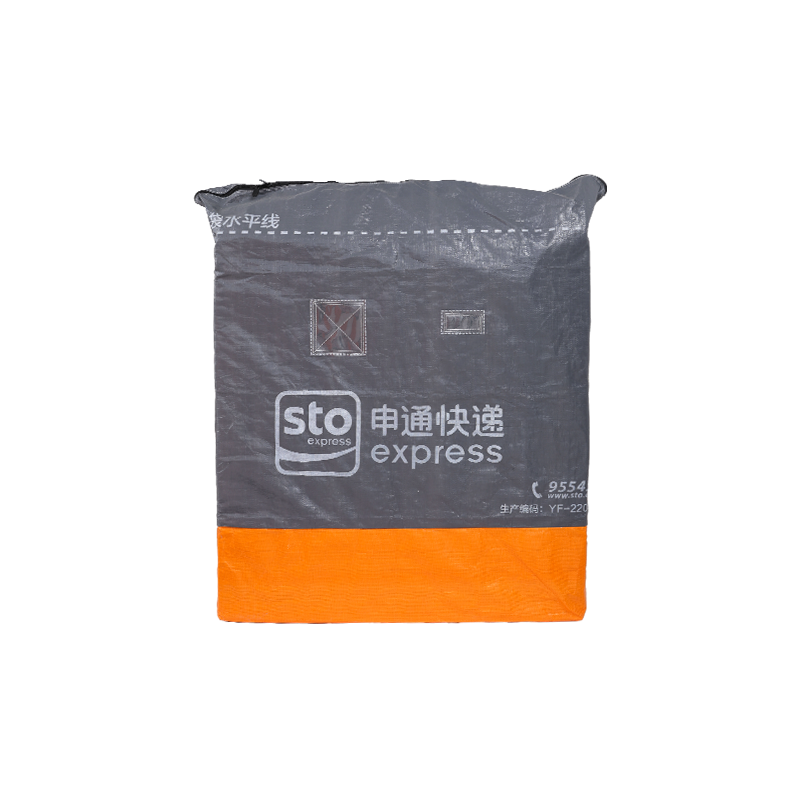

In the process of designing and producing PP Woven postal bags with electronic labels, ensuring the perfect combination of electronic labels and woven bags is crucial. To achieve this goal, we conducted in-depth research on the physical characteristics and usage requirements of electronic tags, including their size, shape, weather resistance, signal transmission distance, etc., in order to reserve suitable installation positions and space when designing woven bags. Through precise calculations and simulation testing, we ensure that the electronic tag can firmly adhere to the woven bag without affecting its normal function and signal transmission.

We have adopted advanced production processes and technological means, such as high-frequency heat sealing, ultrasonic welding, etc., to tightly integrate electronic tags with woven bags. These processes not only ensure the firmness of the connection, but also avoid label detachment or damage caused by external forces during transportation and use.

In addition, we have conducted rigorous testing and validation on the finished products, including vibration testing in simulated transportation environments, waterproof testing, signal transmission stability testing, etc., to ensure that electronic tags can maintain normal working conditions in various complex environments, thereby improving the accuracy and reliability of logistics tracking.

English

English русский

русский