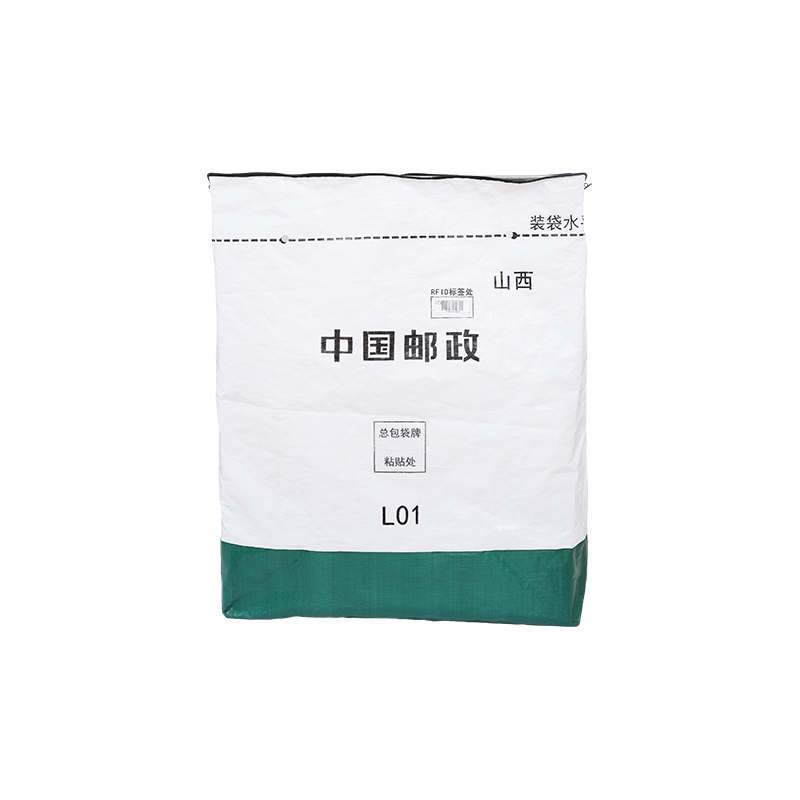

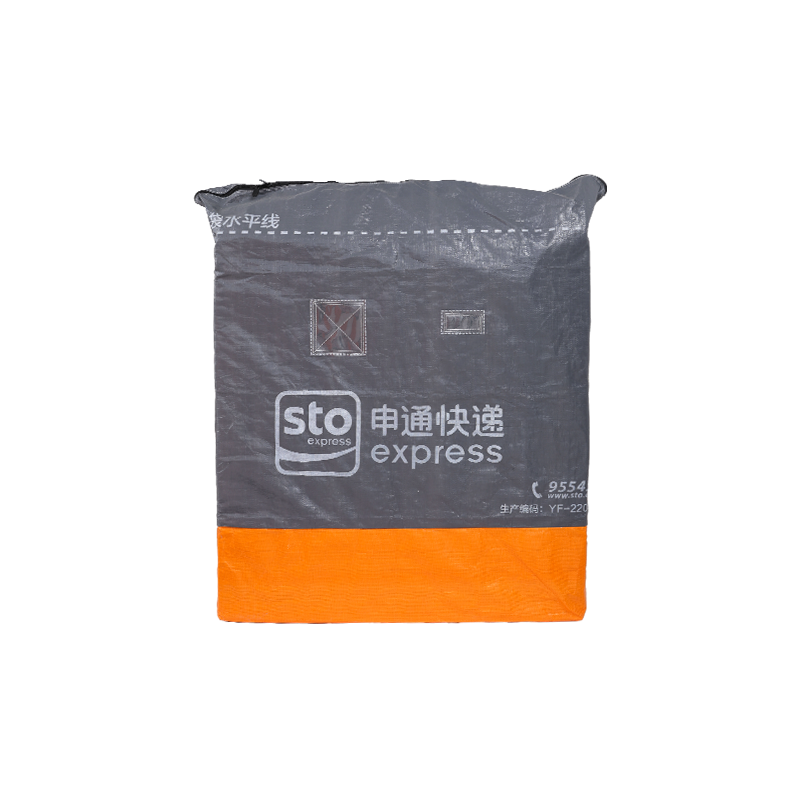

PP woven postal bags are a high-strength, durable and versatile packaging solution commonly used in the postal and logistics industries. This bag is made of polypropylene (PP) woven material with excellent tensile strength and durability. Its special woven structure gives the bag excellent tear resistance, ensuring the safety of items during transportation. Compared with traditional packaging materials, PP woven postal bags are more environmentally friendly and can be used multiple times, reducing the generation of packaging waste.

PP woven postal bags are equipped with electronic tags, this smart technology plays a key role in the logistics and packaging industry.

Tracking and positioning: Electronic tags are embedded with radio frequency identification (RFID) technology, allowing packages to be accurately tracked and positioned throughout the entire logistics link. Logistics companies and customers can obtain the current location information of packages in real time through an electronic platform connected to the logistics management system. This helps improve logistics visibility and reduces the likelihood of packages being lost or stranded.

Real-time data update: Electronic labels can record and update various data about packages in real time, including transportation status, processing time, temperature and humidity, etc. This provides real-time, accurate information to the entire supply chain, helping to achieve more efficient logistics operations.

Improved security: Through electronic tags, the security of packages is improved. Once an abnormality occurs, such as a package being opened or externally damaged, electronic tags can record these events and provide a strong basis for subsequent liability tracing. This is especially important for shipments of high-value items or critical documents.

Optimization of inventory management: Electronic label technology not only plays a role in the transportation process, but is also of great significance in the warehousing process. By deploying RFID technology inside the warehouse, logistics companies can achieve precise monitoring of inventory. Information such as inventory levels, cargo types and storage locations can be obtained in real time through electronic tags, helping to improve the efficiency and accuracy of inventory management.

Automated processing: Electronic labeling technology can be seamlessly integrated with automated equipment to realize automatic processing and classification of packages. This helps increase sorting speed, reduces manual operations, and reduces the risk of human error, thereby improving overall logistics efficiency.

English

English русский

русский