Provide you with the latest enterprise and industry news.

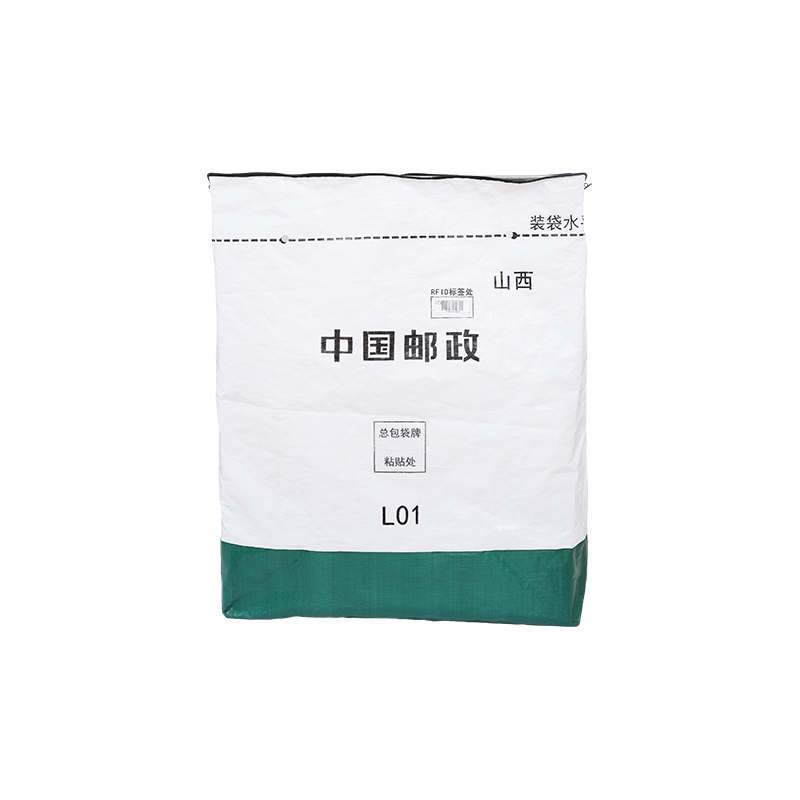

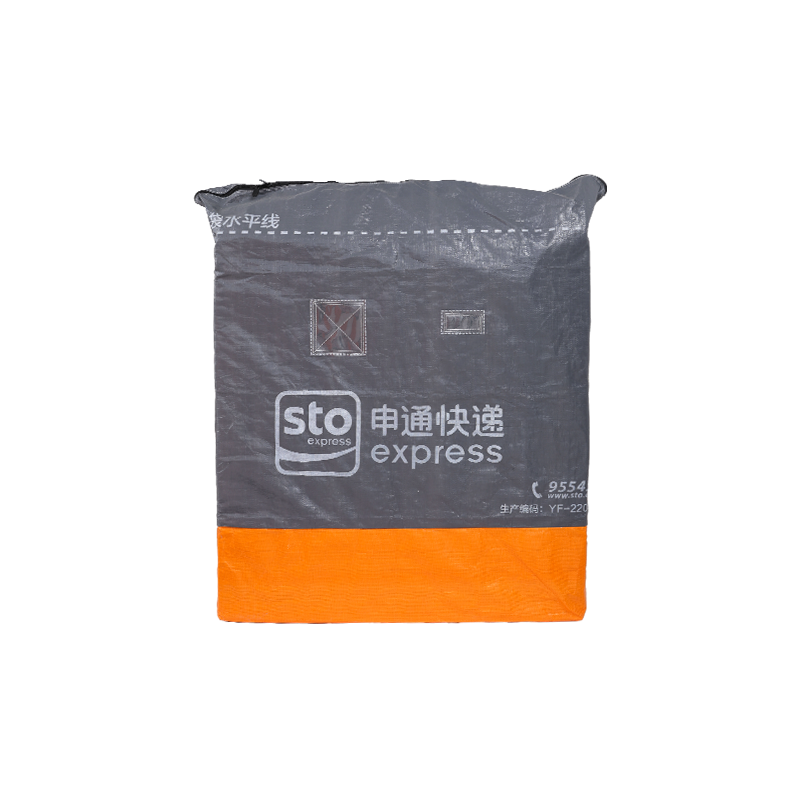

Composite woven bags are widely used in multiple applications due to their excellent durability and tensile strength. The bag's durability is primarily due to its composite construction, which typically includes a mix of materials such as plastic and cellulose. The use of composite materials not only gives the bags excellent abrasion resistance but also significantly increases tensile strength, making them excellent at carrying heavy loads and handling harsh environmental conditions.

In the industrial field, composite woven bags are often used to package and transport various heavy goods and bulk commodities, such as fertilizers, chemicals and cement. These applications place high demands on the tensile strength and durability of the bags. The high tensile strength of composite woven bags means they are able to withstand larger loads without tearing or breakage during transportation. This not only protects the safety of the items inside the bag, but also reduces material waste caused by damaged packaging. In addition, the bag's abrasion resistance resists friction during transportation, reducing the risk of damage. Therefore, in industrial packaging, composite woven bags can effectively reduce transportation and storage costs and improve operating efficiency.

In the agricultural field, composite woven bags are widely used for packaging grain, seeds and fertilizers. These applications also require packaging materials with good durability and tensile strength. The packaging of grain and fertilizer often requires multiple transportation and long-term storage challenges. The durability of composite woven bags can ensure that they remain intact under these conditions and prevent the internal materials from moisture, contamination, or external damage. Especially in humid environments, the water resistance of composite woven bags can effectively protect the internal materials from moisture and maintain their quality and use value.

English

English русский

русский