Provide you with the latest enterprise and industry news.

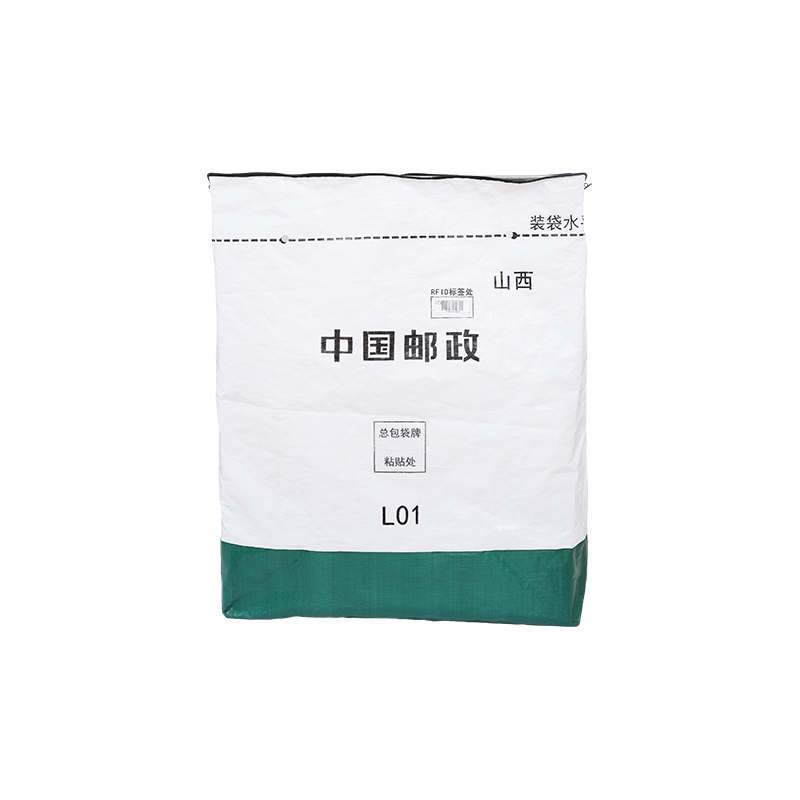

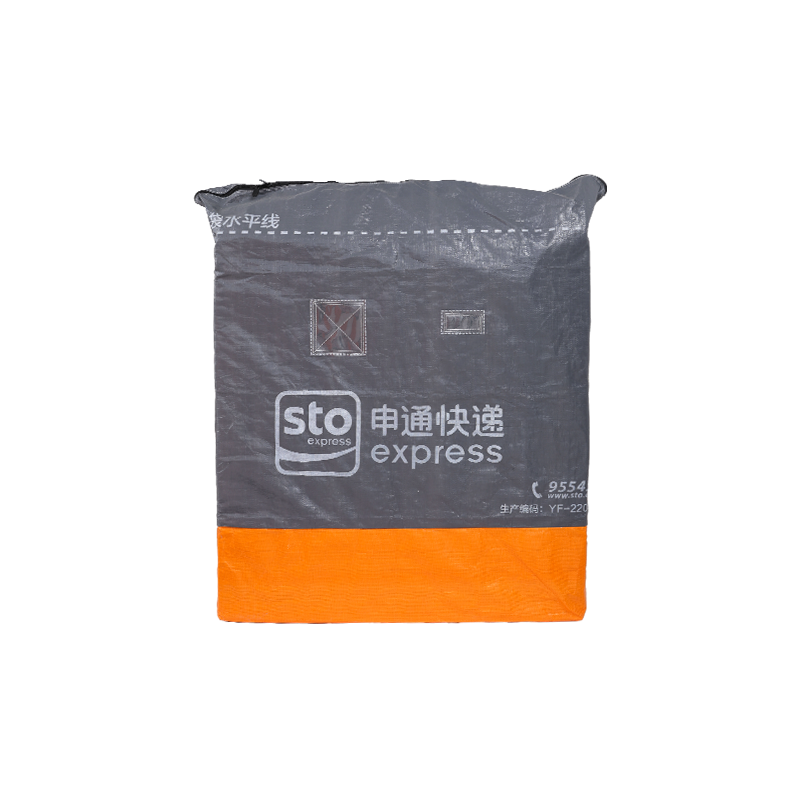

As a common mailing packaging material, the material density of PP woven mailing bags plays a crucial role in its strength and durability. Material density can be understood as the number of polypropylene fibers per unit volume. This parameter directly affects the overall performance and quality of the pouch. When we think about the strength of a pouch, we're actually looking at its load-bearing capacity and resistance to outside pressure and weight. The higher the density, the more closely the fibers of the pouch are interwoven, which means there are more fibers in the same volume and therefore more fibers sharing externally applied forces. As a result, high-density mailing bags generally have a greater load-bearing capacity and can better protect mail items from damage.

On the other hand, density also affects the durability of the pouch. Durability generally refers to a mailer's ability to resist wear, tear, and other forms of damage during use. A denser pouch means more fibers are spread over the same area so that they are more closely connected, creating a stronger structure. This structure makes the pouch more difficult to get scratched or torn, and therefore more able to withstand the challenges and tests of use. In the long run, this means high-density pouches have a longer lifespan, maintaining their performance and integrity over multiple uses.

When we consider choosing a mailing bag, we need to consider its strength and durability as well as other factors such as cost and environmental friendliness. While higher-density mailing bags generally have better performance, they can also be more expensive to manufacture. Therefore, we need to find the best balance point to meet specific usage needs and budget constraints while ensuring quality.

English

English русский

русский